Bionetics manufactures instruments used to measure basic and advanced power plant condenser operating parameters, provides services to guide selection of actionable items for achieving and maintaining maximum condenser performance, and engineers solutions to remedy unsolved condenser problems.

Air In-Leak Monitoring

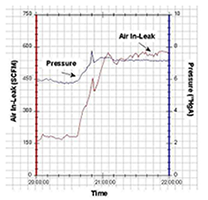

Bionetics’ RheoVac Condenser Monitor provides accurate measurement of air being removed from the condenser by the vacuum pumps/air ejectors. By measuring air in-leakage flow between the condenser and the exhauster(s), the RheoVac instrument gives a true continuous reading of condenser air in-leakage passing through the condenser. Measurements made at the exhauster discharge are often inaccurate regarding leaks in the condenser as they include air in-leakage at the exhauster seals and also vent line isolation valves.

A Texas plant had one of its 500+MW units running at extremely high condenser backpressure. Initial readings on the RheoVac monitor showed a very high level of air in-leakage into the condenser. Plant personnel thought that the main feed pump might be the likely source of the leakage, so operators switched to a motor-driven pump. That change actually resulted in air in-leakage increasing to nearly 4 times the previously high reading which lead them to continue to search for the source of the leak. They were able to find that a 4-in. gland steam pipe had ruptured inside the condenser. The RheoVac instruments’ ability to do continuous monitoring and diagnostics enabled the plant to address the situation before it escalated further and has helped them continue to operate more efficiently.

A Texas plant had one of its 500+MW units running at extremely high condenser backpressure. Initial readings on the RheoVac monitor showed a very high level of air in-leakage into the condenser. Plant personnel thought that the main feed pump might be the likely source of the leakage, so operators switched to a motor-driven pump. That change actually resulted in air in-leakage increasing to nearly 4 times the previously high reading which lead them to continue to search for the source of the leak. They were able to find that a 4-in. gland steam pipe had ruptured inside the condenser. The RheoVac instruments’ ability to do continuous monitoring and diagnostics enabled the plant to address the situation before it escalated further and has helped them continue to operate more efficiently.

Excess Backpressure and Dissolved Oxygen Reduction

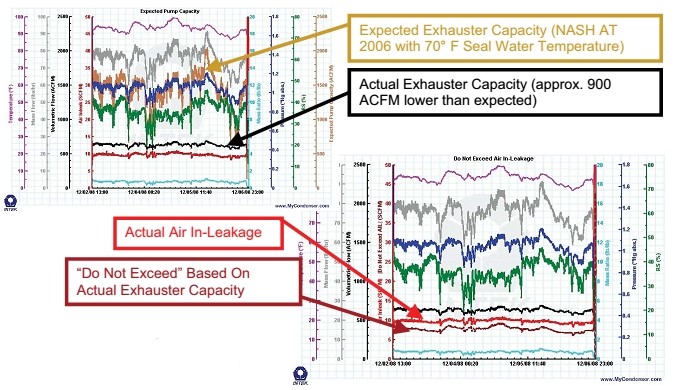

The RheoVac Condenser Monitor provides a direct measurement of exhauster performance and shows if air in-leakage is affecting condenser performance. With this information, the identification of root causes for excess condenser pressure and condensate dissolved oxygen can be made.

By measuring exhauster capacity, it can be determined if maintenance action should focus on exhausters or air ingress. In the example shown on the charts here, it can be seen that the NASH AT2006 pump is operating well below its rated capacity, resulting in excess condenser pressure. This customer now has the necessary information to direct a maintenance action to repair the exhauster and recover >0.2”Hg excess turbine back pressure.

Power Plant Performance Improvement

Condenser retrofit projects by Bionetics have achieved actual values of 1.0”Hg lower condenser pressure, condensate dissolved oxygen under 5 ppb (before the condensate pump), immunity to air in-leakage of 80 SCFM, and 5 to 10MW of increased generation.

Proven Solutions to Condenser Performance Problems

Bionetics offers a range of services in addition to our unique condenser instrumentation to help you identify and resolve performance issues with your condenser that are costing you money. Email us sales-flow@bionetics.com or Contact Us using the form on this page to describe your plant performance concerns and let us help you achieve the results you are looking for from your operations.